Our comprehensive drive portfolio

Customized drive solutions

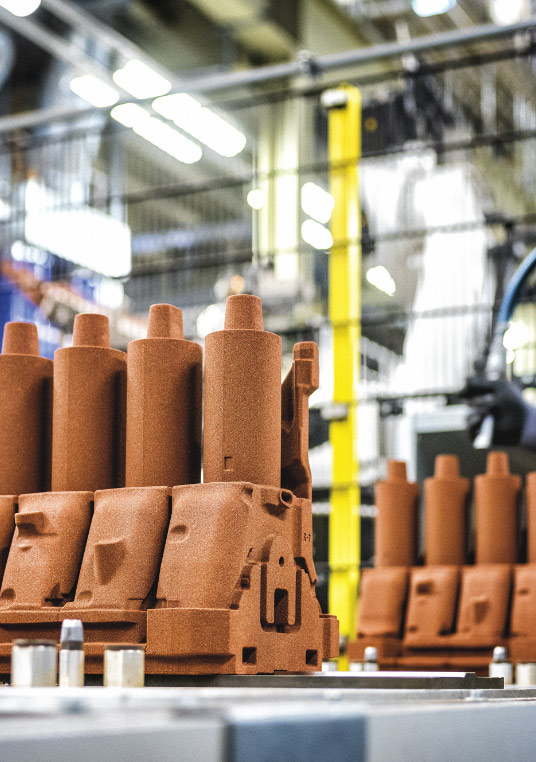

Our interdisciplinary team consists of experienced foundrymen and experts in the fields of iron casting, engineering and design. Whether cylinder crankcases, cylinder heads, heavy hydraulics, electric motors or heat pump housings: our drive portfolio includes applications in the automotive, marine, energy and control technology sectors. We use state-of-the-art simulation methods during development to ensure the quality of our products and more effective planning and control of component design at all times.

Project management

We use state-of-the-art project tools and structures to plan, organize, manage and control our new parts and development projects. The composition of our teams is multidisciplinary and includes all relevant departments.

Product optimization

We take a comprehensive approach to manufacturing processes: we ensure the castability of even the most complex components in large series and promote the integration of lightweight construction and functional optimization.

Simulation and construction

Our developers simulate core manufacturing and casting processes with MAGMASOFT software. The results are evaluated by our simulation engineers in order to initiate preventive measures in good time.

Additive manufacturing

With the help of our additive manufacturing, we create 3D prints to produce prototypes at an early stage ("rapid prototyping"), which are designed close to series production. This allows us to present designs before expensive series tools are even produced.

Material optimization

We cast iron in all types of cast iron - whether GJL 250, molybdenum alloys, GJV 450 or GJS. We develop product-specific solutions for our customers, such as our patented VARIFER®.

Do you have any questions about our drive components? We are happy to help you with our know-how.